-

Reducing inventory to improve costs

The economic crisis is showing signs of falling behind, but that does not mean money is piling up, let alone that it is time to loosen control and the urge to cut back unnecessary expenses. Inventory management is one area where it is always possible to improve. Depending on the type of product your company…

-

Understanding production chains

We always talk about the supply chain, the value chain, production chains, but we rarely take the time to stop and think about what these different chains mean in practice. In this post, we are going to demystify production chains, how they relate and what they have to do with us, consumers of the final…

-

Facility layout as a logistic tool

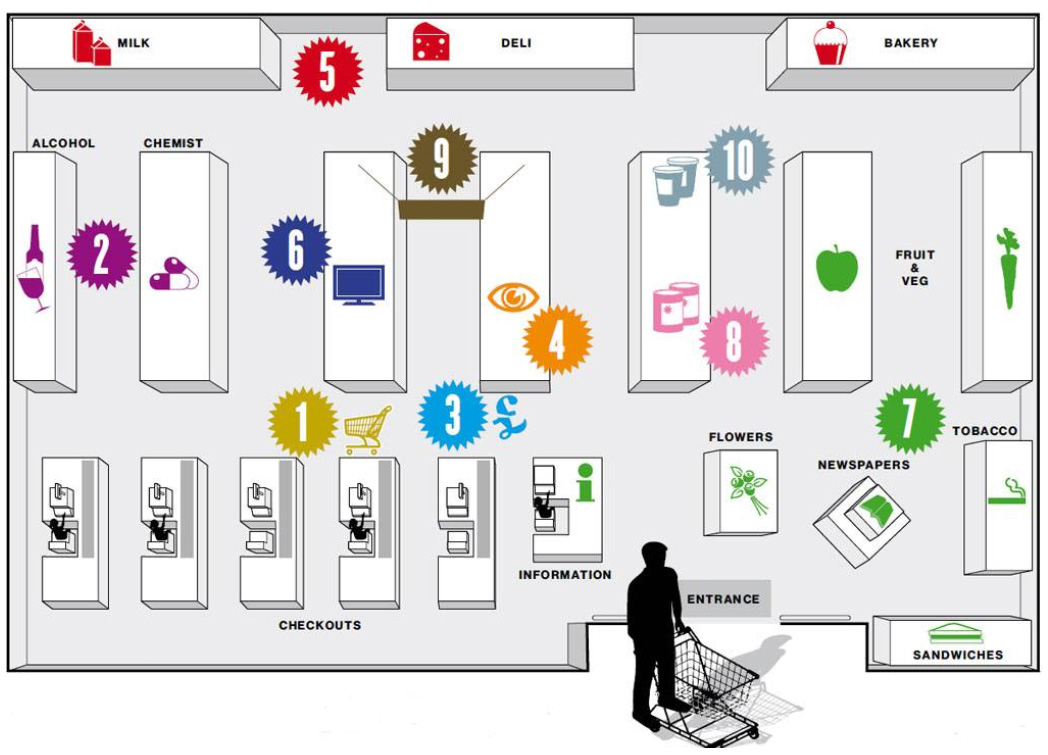

Facility layout deals with arranging things within a facility. The things being place can be workshops in plants, machines, workstations, sections, offices… the facility in which these things are placed can be production plans, assembly lines, offices, workshops, etc. Simply enumerating all possible combinations of locations is not an easy task due to the geometric…

-

Quality management

Quality is a subjective topic. Different people experience the same product differently. For example, how hot should your coffee be? Each one has a different measure, and this affects how they perceive the quality of the coffee. In more technical terms, quality is the set of characteristics of a product (or service) which have an…

-

Scheduling: rules and performance indicators

Scheduling aims at controlling and balancing workload from tasks to resources in a production system. Many of its characteristics and goals are covered in our post Scheduling Problems. Here, we focus on solving the problem and measuring the quality of a schedule plan. Sequencing rules Given a set of orders, how to assign them to…

-

Scheduling problems

Scheduling problems appear in several industries. A manufacturing company must decide the sequence and machines used in the production process of each product; a delivery company must decide on the sequence of customers to visit; a transportation company must determine which of its vehicles to use in the trips. Take an airline company for instance. How many…

-

Key Performance Indicators (KPIs) for Inventory Planning and Control

Keeping inventories at the exact desired level is not an easy task. It requires coordination between purchasing, sales, forecasting and demand planning. Very high inventories guarantee demand satisfaction but incur high costs. Low inventories ensure low maintenance costs but involves the risk of losing sales, which represent a very high intangible cost. Let’s look at…

-

Key Performance Indicators (KPIs) for transportation

In this post we will see some examples of key performance indicators (KPIs) for the transportation sector, one of the most important for logistics and for the supply chains in general, since its cost has a direct impact on the bottom lines of companies and in the cost of products paid by the final consumer.…

-

Key performance indicators

Key performance indicators (KPI) serve to assess and measure the performance level of important processes for businesses. They are widely used by managers to direct the efforts of employees and partners to improve the most important indexes. Performance indicators are unique for each company, as they should reflect the company strategy. Thus, in the logistics…

-

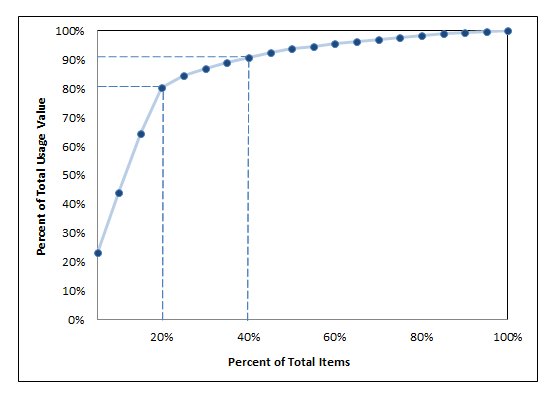

The ABC analysis and classification

The ABC analysis is one of the tools the most used in logistics and needs to be well understood. The ABC analysis, also called the ABC Classification or Pareto Theorem (named after its creator), was born when he realized that 80% of the wealth was in the hands of only 20% of the population. This…